Hello, my name is Emily Conkling and I’m a junior in

Environmental and Ecological Engineering. This past summer, I worked with Dr.

Andrew Whelton through the Purdue SURF (Summer Undergraduate Research

Fellowship) Program.

|

| These are pictures of me during my SURF presentation, and during field work in California. |

The project I worked on studied the environmental affects

and occupational hazards of working with cured-in-place pipe (or CIPP). CIPP is

a method of repairing faulty sewer and storm water pipes. This method involves

inverting a resin-impregnated tube into the faulty pipe and curing it in place

- basically making a new pipe within the old one. It’s a convenient option

because the new pipe can be installed in one day, and it doesn’t involve

tearing up asphalt or concrete or cause any long-term road construction.

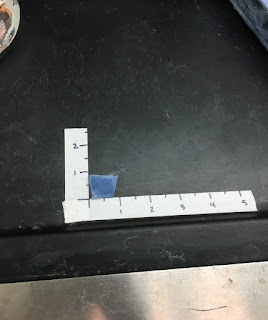

The left picture is a piece of rehabilitated pipe. The CIPP is the blue pipe that sits within the old pipe. The right picture shows what the uncured resin looks like before it is cured within a pipe, like in the left picture.

One issue with CIPP is that its chemical composition (and

therefore its environmental effects) are very poorly understood. We know that

it’s fiberglass reinforced and contains a chemical compound called styrene, but

other than that, we don’t know much. Despite this lack of knowledge, this CIPP

resin has been assumed to be the cause of downstream fish kills and algal

blooms, and adverse health effects in humans. So my team and I set out to find

out what exactly was happening with this stuff.

|

| Dr. Whelton and Professor Howarter on site at Purdue |

One of the first things we looked at was the resin itself,

both cured and uncured. We analyzed these by putting little pieces of it in different

solvents, which basically break down and extract whatever chemicals are in the

CIPP resin. Once those ‘soaked’ for 14 days, the solvent was put into the GC/MS

(Gas Chromatography/Mass Spectrometry). This machine divides up the chemicals

and tells you what they are based on molecular weight. This whole process told

us some of the chemicals present in CIPP and its resin.

The next step was to figure out what chemicals escaped during

the CIPP installation. Luckily for us, there were a few installations scheduled

for Purdue’s campus. We took monitoring and sampling equipment with us to the

installation. We brought a photoionization detector (or PID) which was

calibrated to measure the concentration of styrene in the air. We also brought

pumps with sorbent tubes attached, and bag sampling pumps. The sorbent tubes

are little metal tubes about 4” long and chemicals in the air sorb, or stick,

on to the tube. You can then take this tube back to the lab and analyze it

using the GC/MS. Bag sampling pumps are pumps that suck the surrounding air

into a tedlar bag, which is a laboratory-grade Ziploc bag. Again, you can

analyze the bags of air using the GC/MS.

All of this work was done in preparation for doing field

work in California. We wanted to make sure we had a good idea of what to look

for before we packed up all the equipment and headed west. In early August, we

loaded up a Purdue van, and made the 40 hour trek to Sacramento, California.

|

| We stopped in Laramie, Wyoming the first night. I took this picture before we got back on the interstate in the morning. |

|

| We also stopped by the Bonneville Salt Flats in Utah, home of the world land speed records. |

|

| Team meeting before field work begins |

|

| Have to make sure the respirators fit! |

For the most part, we used the same procedure in California

as we did at Purdue, just on a larger scale. One main difference was that we

took a stainless steel apparatus to California. The purpose of this device was

to integrate all of the equipment I talked about before into one big system.

Instead of having one machine over here and another machine over there, all of

our field equipment was side-by-side. This made things easier for us to

operate, and also helped ensure that our data would be comparable.

|

| This is me prepping a PID before we begin our work for the day. |

|

| This is our lab in California. As you can see, we pack light. |

Now that we are back in our lab at Purdue, all the analyzing

begins. The tedlar bags were analyzed first, followed by the sorbent tubes.

Next on the docket is uncured and cured CIPP samples, followed by other things

collected on site.

Going into the SURF program, I wasn’t sure what I would

think of it. I assumed that I’d be stuck in a lab working on something that

wouldn’t really be applicable in the ‘real world.’ And I’m glad that SURF

proved me wrong. My work this summer got me outside, doing something different

every day, and it’s something that will have direct impacts on the real world. Undergraduate

research is definitely something I have grown to really like, and I highly

recommend it to other students. It’s a great way to meet other students, get to

know faculty, and get some really good experience that will make you valuable to

recruiters. After this experience, I am seriously considering getting a

Master’s degree, and I’m incredibly thankful for my research team, SURF, and

Purdue. Boiler Up!

No comments:

Post a Comment